From Idea to Prototype: Stevens Expands Spaces for Innovation

The MakerCenter is a gathering point where communities of new and experienced makers connect to create and explore

From America’s first steam ferry and commuter trains in the 19th Century to the pathbreaking new technologies and solutions created by students and faculty – making things has always been part of Stevens Institute of Technology’s history. This spring, with the newly launched MakerCenter, the tradition of making at Stevens continues.

The MakerCenter is the Stevens design hub – a collective of spaces and labs for Stevens students and researchers to collaborate and build their latest innovations. The MakerCenter facilities and services are made up of the previously existing Prototype Object Fabrication (ProOF) Lab where students can work with staff members to fabricate parts, the new Quantum Space where students can learn about quantum engineering and test their quantum devices, and the newly dubbed MakerSpace, which provides tools and equipment for students to design and build their own prototypes. The facility also houses machining, electronics, and welding services.

The new collection of spaces provides the Stevens community with the facilities and tools needed to explore, design, and engineer new technologies and innovations.

“The Maker Center provides flexible space, necessary tools, and training [for students and faculty] to assemble and test their designs. Together with other resources, students are able to design and realize complex systems as part of their academic work or academic entrepreneurship,” said Kishore Pochiraju, professor and associate dean for undergraduate studies, Department of Mechanical Engineering, who also directs the ProOF lab.

The MakerSpace is housed in the ABS R – 104 Collaborative Design and Prototyping Lab. Stevens undergraduates, graduate students, faculty and staff, part-time and full-time, are eligible for access to the MakerSpace.

The sound of innovation and collaboration

Amid the sounds of hand and power tools drilling fasteners, nuts and bolts, and the clanging of metal at the ABS Engineering Center at Stevens, you may find students and faculty getting their hands dirty designing and making something innovative.

There, at the new MakerSpace, members of the Stevens academic community are also putting their engineering knowledge to work. And if you listen closely, you may even hear the sounds of collaboration.

“The MakerSpace is a gathering point connecting communities of new and experienced makers to work on real and personally meaningful projects,” said Paul McClelland, technical services center manager at Stevens’ Schaefer School of Engineering & Science.

In addition to facilitating connections, the MakerSpace also helps meet the increasing demand for hands-on learning opportunities on campus. This soup-to-nuts community space encourages creative learning and helps to reinforce the engineering concepts and skills discussed in the classroom.

“The MakerSpace helps students engage in reality where the student’s design goes from concept to a working prototype,” said McClelland. “It helps students focus on the details that are involved when specifying an actual prototype.”

A place for creativity and innovative ideas

Makerspaces foster innovation and creativity and provide opportunities for collaborative work and problem-solving. Whether someone dreams of making a prototype of the next engineering marvel or wants to tinker with all types of tools to get inspired, ideas can come to life at Stevens’ MakerSpace.

The MakerSpace increases access to resources, such as materials, equipment and tools for fabrication and measurement, allowing members of the Stevens community to create, explore and drive their ideas toward realization.

McClelland explained that automated tool cabinets offer a full complement of hand and power tools, electronic tools, and metrology (measurement) tools. Additional resources include an electronics bench, soldering and electronic assembly capabilities, standard and metric, thread gages, tap and die sets, and commonly used fasteners, nuts, bolts and washers.

Expert support available onsite

Trained support staff can help guide students and faculty on the safe and proper way to use the technologies and traditional tools and equipment available at MakerSpace.

Onsite mentors and experts are also available to support most types of research projects, including class and senior projects involving prototyping and manufacturing.

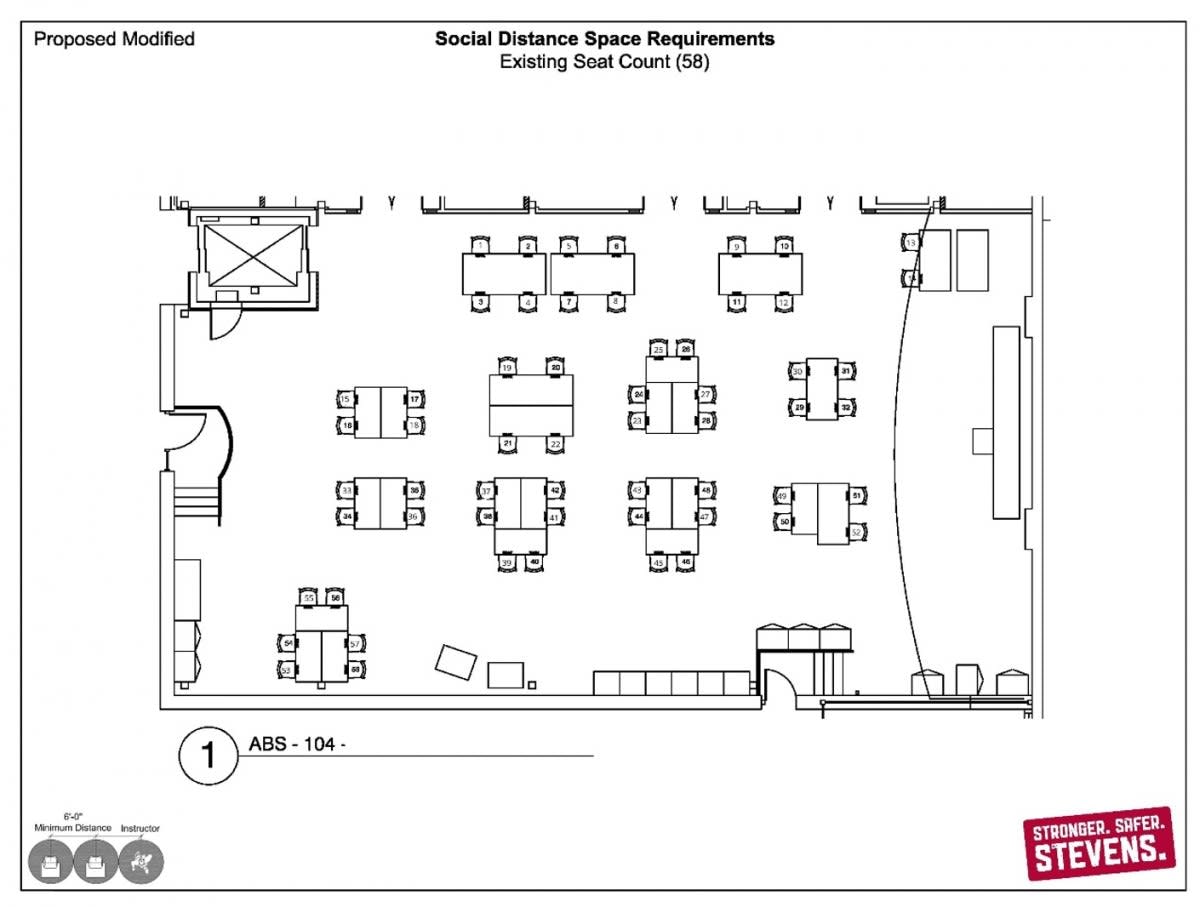

The MakerSpace follows complete COVID-19 protocols and safety measures per Stevens’ guidelines. Anyone entering the MakerSpace is asked to log in and out via QR code on their smartphone at the bench and seat that they intend to occupy during their visit. This provides the staff the ability to do contract tracing in the case of an outbreak and track usage trends. The MakerSpace also provides face masks, sanitary wipes, and gloves. Bench seating is limited to 50% and seating is swapped between sessions.